Robot for Semiconductor

STCR4160SN (Closed-loop control)4-Axis Cylindrical Coordinate Clean Robot

|

Usage Environment/SpecificationsProduct Profile

|

List of Product Model

| Product Model & Vertical Stroke | |||

|---|---|---|---|

| STCR4160SN-200-CM | 200mm | ||

| STCR4160SN-300-CM | 300mm | ||

| STCR4160SN-400-CM | 400mm | ||

| STCR4160SN-450-CM | 450mm | ||

| STCR4160SN-500-CM | 500mm | ||

Product Video

- The image above is of STCR4160SN-300-CM and the video shows STCR4160SN-300-PM.

Characteristics

Path planning handling has joined the lineup of clean robot with the closed-loop control.

Access to the chamber stage arranged in parallel without a track improves the flexibility in the layout design and the cost-performance.

*Click to go to the page of the path planning handling video.

New type of 4-axis cylindrical coordinate type twin-arm clean robot

For handling wafers from 2 inch to 300mm with low-cost, high-speed handling, and no step-out error

- High reliability: Closed-loop control achieves no step-out error under rapid load change or acceleration.

- Reduced origin search time: By absolute encoder

- Equipped with the batteryless multi-rotation absolute sensor

- Robot replacement is available: Compatible with conventional model (installation/performance)

- High rigidity: Payload capacity of 3kg (calculated for the arm 3rd joint/including wrist-block, end-effector, and wafer)

- Arm lineup: 100mm, 130mm, 160mm, 200mm

- Base or flange mounting type is selectable according to the customer’s system layout.

- Bernoulli end-effector is available (option)

Standard Specifications

| Specifications of Robot | ||||

|---|---|---|---|---|

| Robot Model | STCR4160SN-300-CM | |||

| Carrying Object | Wafer up to 300mm (Available for various types of wafers) | |||

| Wafer Holding Method | By vacuum suction | |||

| Robot Model Type | Cylindrical coordinate type | Control Axis | 4-axis | |

| Motor Type | Stepping motor (Closed-loop) | |||

| Operating Range | From the robot center to the wafer center | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 575mm | 340deg | 300mm | ||

| Carrying Speed (Ave.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 570mm/sec | 220deg/sec | 200mm/sec | ||

| Carrying Speed (Max.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 1140mm/sec | 270deg/sec | 250mm/sec | ||

| Resolution | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| Below 10.0µm | 0.0015deg | 2.0µm | ||

| Repeatability | Within ±0.1mm | |||

| Cleanliness | ISO Class 2 (at wafer transfer level when exhausting driving part) | |||

| Utility | Power: DC24V±10% 10A Vacuum: -53kPa or more | |||

| Mass | Approx. 30kg | |||

| Specifications of Controller | ||||

| Controller Model | C4000B series | |||

| Interface | RS232C and parallel photo I/O | |||

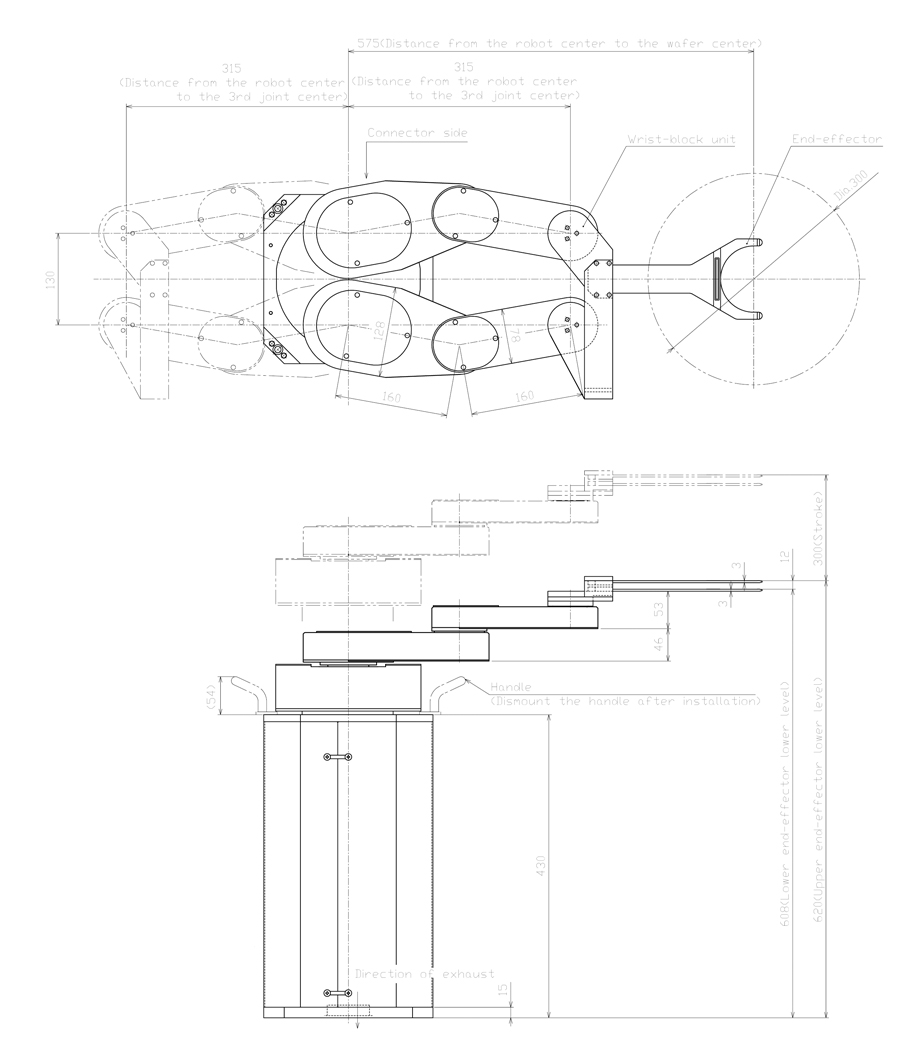

| Outline Drawing (Standard) |

|---|

|

Option

Wrist-Block Unit

| Model Name | Total Length | Mapping Sensor | Thickness of Attaching End-Effector |

|---|---|---|---|

| SART08674 | 60mm | 2mm | |

| SART08604 | 60mm | 2mm | |

| SART08675 | 155mm | 2mm | |

| SART08661 | 155mm | Available | 2mm |

| SART08676 | 60mm | 2mm | |

| SART08668 | 60mm | Available | 2mm |

*The table above shows the specifications of JEL standard wrist-block units. The other specifications are available.

*Click the items below to review the wrist-block units other than JEL standard types.

End-Effector

| Model Name | Size of Carrying Object | End-effector Type (Thickness) | Wafer Holding Method |

|---|---|---|---|

| SC-IW-200 | 3 inch, 100mm to 200mm | I-shape (2mm) | Vacuum suction |

| SC-IW-240 | 3 inch, 100mm to 300mm | I-shape (2mm) | Vacuum suction |

| SC-YW-200 | 100mm to 200mm | Y-shape (2mm) | Vacuum suction |

| SC-YW-227 | 100mm to 300mm | Y-shape (2mm) | Vacuum suction |

| SC-YW-240 | 100mm to 300mm | Y-shape (2mm) | Vacuum suction |

| 3D-02229 | 150mm to 300mm | Y-shape (2mm) | Vacuum suction |

| SC3-YW-240 | 300mm | Y-shape (3mm) | Vacuum suction |

| 3D-01661 | 300mm | Y-shape (3mm) | Vacuum suction |

| SC3-IW-240 | 300mm | I-shape (3mm) | Vacuum suction |

*The table above shows the specifications of JEL standard end-effectors. The other specifications are available.

*Click the items below to review the end-effectors other than JEL standard types.

Operating Range

| End-Effector/Wrist-Block Unit | SART08674 | SART08604 | SART08675 | SART08661 | SART08676 | SART08668 |

|---|---|---|---|---|---|---|

| SC-IW-200 | 525mm | 525mm | 620mm | 620mm | 525mm | 525mm |

| SC-IW-240 | 565mm | 565mm | 660mm | 660mm | 565mm | 565mm |

| SC-YW-200 | 535mm | 535mm | 630mm | 630mm | 535mm | 535mm |

| SC-YW-227 | 535mm | 535mm | 630mm | 630mm | 535mm | 535mm |

| SC-YW-240 | 575mm | 575mm | 670mm | 670mm | 575mm | 575mm |

| 3D-02229 | 575mm | 575mm | 670mm | 670mm | 575mm | 575mm |

| SC3-YW-240 | 575mm | 575mm | 670mm | 670mm | 575mm | 575mm |

| 3D-01661 | 575mm | 575mm | 670mm | 670mm | 575mm | 575mm | SC3-IW-240 | 565mm | 565mm | 660mm | 660mm | 565mm | 565mm |

Other Option

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking