Bernoulli Hand

|

Usage Environment/SpecificationsProduct Profile

|

Product Video

Characteristics

Light and compact, the Bernoulli hand holds thin wafers using the Bernoulli principle.

Wafer breakage risk is minimized due to non-suction holding.

With the flexible front edge, the Bernoulli hand picks up wafers from the wafer containers or wafer cassettes and places wafers in them.

Accessible to various substrates as well as wafers.

- Wafers can be lifted by the Cyclone effect.

- Wafer holding by the pad (Fluorine-contained rubber)

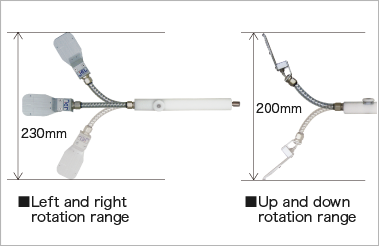

- The operator can adjust the hand in various angles with a flexible tube.

Standard Specifications

| Carrying object | 2 to 3 inch, 100 to 150mm wafer |

|---|---|

| Material | Aluminum |

| Surface treatment | Cyclone pad: Black alumite; Other parts of front edge: White alumite |

| Wafer holding | By the Bernoulli’s principle using Cyclone pad |

| Payload | Below 50g |

| Environment of operation | Clean air, N2 |

| Supply pressure | Below 0.3MPa (Connection port) |

| Maximum air flow | 15L/min |

| Mass | 110g |

- No oil is required for the slide parts of release switch.

- No. of cyclone pads used in standard model: 1 piece

- Wafer holding by the pad (Fluorine-contained rubber)

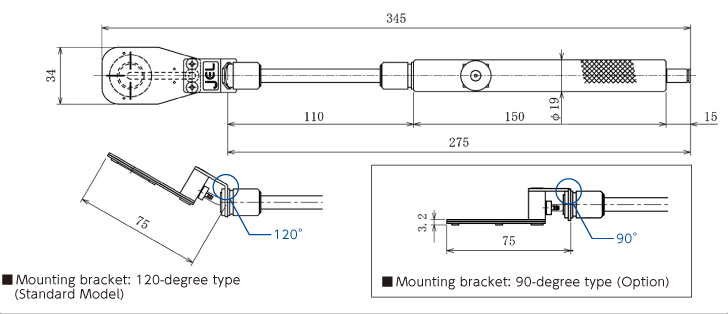

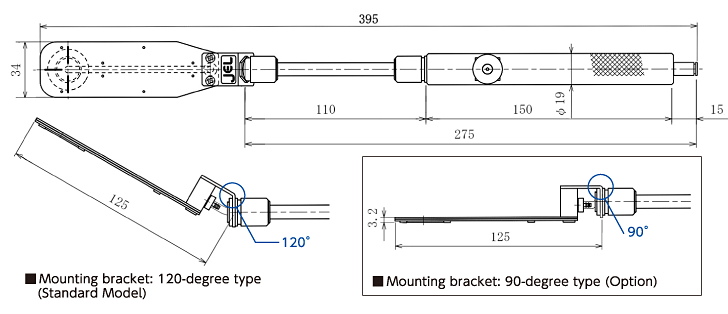

- Mounting bracket: 120-degree type (Standard Model), 90-degree type (Option)

Please contact us for the detailed specifications.

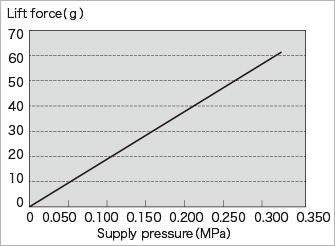

Pressure and lift force diagram

Operating range of flexible tube

Model No.

Two types of Bernoulli Hand are available.

BRP-01 is a short front edge type, which is suitable for horizontal installation or wafer containers.

BRP-02 is a long front edge type, which is suitable for horizontally-mounted cassettes.

| BRP-01(Short front edge) |

|---|

|

| BRP-02(Long front edge) |

|

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking