Robot for Semiconductor

MTCR41604-Axis Cylindrical Coordinate Clean Robot

|

Usage Environment/SpecificationsProduct Profile

|

List of Product Model

| Product Model & Vertical Stroke | |||

|---|---|---|---|

| Standard | MTCR4160-300-AM | 300mm | |

| MTCR4160-400-AM | 400mm | ||

| MTCR4160-500-AM | 500mm | ||

Product Video

- The image above and the video are of MTCR4160-300-AM.

Characteristics

Designed for handling 300mm wafers in a production line or inspection line of semiconductor.

High-speed handling by AC servo motor and superior cost performance compared to MTHR type.

Certified CE marking.

Execution of origin search is not required by using the servo motors with absolute encoders.

- Arm lineup: 160mm, 200mm

- Twin-arm reduces the wafer swap time.

- Base or flange mounting type is selectable.

- Motion monitoring is available.

- RS232C and parallel photo I/O are standard for control.

- AC servo motor installed in all axes.

- High-speed, high-accuracy wafer handlingby S-curved speed control.

- Wafer holding: end-effector with vacuum suction, passive edge, edge grip, or Bernoulli type End-effector.

- End-effector material: CFRP, Al, ceramic, or others.

- Optimal end-effector is selectable according to the carrying object and line layout.

Standard Specifications

| Specifications of Robot | ||||

|---|---|---|---|---|

| Robot Model | MTCR4160-300-AM | |||

| Carrying Object | Wafer up to 300mm | |||

| Wafer Holding Method | By vacuum suction | |||

| Robot Model Type | Cylindrical coordinate type | Control Axis | 4-axis | |

| Motor Type | AC servo motor | |||

| Operating Range | From the robot center to the wafer center | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 575mm | 340deg | 300mm | ||

| Carrying Speed(Ave.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 850mm/sec | 340deg/sec | 330mm/sec | ||

| Carrying Speed (Max.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 1800mm/sec | 550deg/sec | 500mm/sec | ||

| Resolution | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| Below 9.82µm | 0.0015deg | 1.96µm | ||

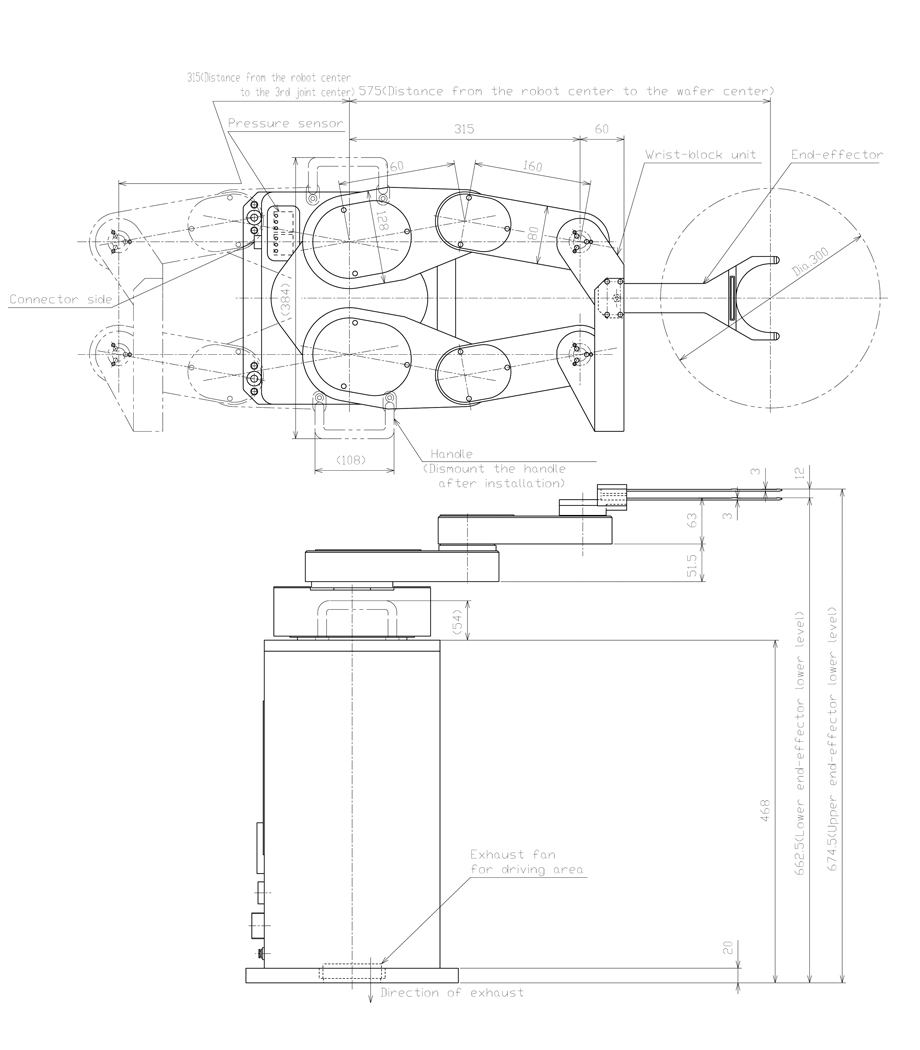

| Handling level | 674.5mm (Base mounting level to end-effector level) | |||

| Repeatability | Within ±0.1mm | |||

| Cleanliness | ISO Class 2 (at wafer transfer level when exhausting driving part) | |||

| Utility | Power: AC200V single phase ±10% 3kVA; Vacuum: -53kPa or more | |||

| Specifications of Controller | ||||

| Controller Model | C5000S series | |||

| Interface | RS232C and parallel photo I/O | |||

| Outline Drawing (Standard) |

|---|

|

Option

End-Effector

| Model Name | Size of Carrying Object | End-effector Type (Thickness) | Wafer Holding Method |

|---|---|---|---|

| SC-IW-200 | 3 inch, 100mm to 200mm | I-shape (2mm) | Vacuum suction |

| SC-IW-240 | 3 inch, 100mm to 300mm | I-shape (2mm) | Vacuum suction |

| SC-YW-200 | 100mm to 200mm | Y-shape (2mm) | Vacuum suction |

| SC-YW-227 | 100mm to 300mm | Y-shape (2mm) | Vacuum suction |

| SC-YW-240 | 100mm to 300mm | Y-shape (2mm) | Vacuum suction |

| 3D-02229 | 150mm~300mm | Y-shape (2mm) | Vacuum suction |

| SC3-YW-240 | 300mm | Y-shape (3mm) | Vacuum suction |

| 3D-01661 | 300mm | Y-shape (3mm) | Vacuum suction |

| SC3-IW-240 | 300mm | I-shape (3mm) | Vacuum suction |

*The table above shows the specifications of JEL standard end-effectors. The other specifications are available.

*Click the items below to review the end-effectors other than JEL standard types.

Other Option

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking