Robot for Semiconductor

GTFR5280 (For 300 mm wafer)5-Axis Horizontal and Multi-Joint Type Clean Robot

|

Usage Environment/Specifications

Product Profile

|

List of Product Model

| Product Model & Vertical Stroke | |||

|---|---|---|---|

| Standard | GTFR5280-320-DM | 320mm | |

Product Video

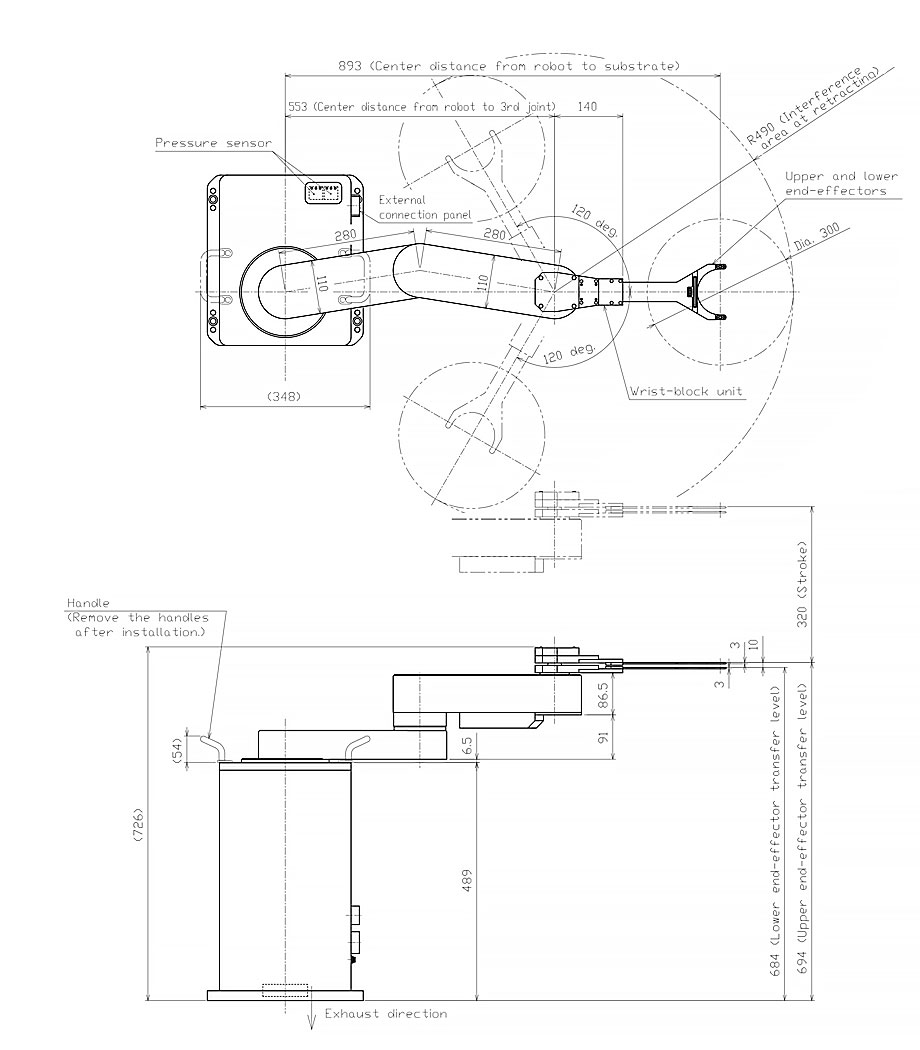

- The image above and the video are of GTFR5280-320-DM.

Characteristics

5-Axis horizontal and multi-joint type clean robot for 300 mm wafer.

A twin end-effector mounted on its single-arm has the same function as a twin-arm robot.

Designed for handling wafers in EFEM.

Compared to our conventional GTCR model, the cycle time is improved by reducing the operation prohibited area and the influence of speed limit.

- 3 FOUP access is available without a track.

- Twin end-effector reduces the wafer swap time.

- AC servo motors with absolute encoders installed. (Batteryless)/ Direct Drive Motor

- Wafer holding: end-effector with vacuum suction, passive edge, edge grip.

- Optimal end-effector is selectable according to the carrying object and line layout.

Standard Specifications

| Specifications of Robot | ||||

|---|---|---|---|---|

| Robot Model | GTFR5280-320-DM | |||

| Carrying Object | Up to 300 mm silicon wafer | |||

| Wafer Holding Method | By vacuum suction | |||

| Robot Model Type | Horizontal and multi-joint type | Control Axis | 5-axis | |

| Motor Type | AC servo motor (Batteryless)/ Direct Drive Motor | |||

| Operating Range | From the robot center to the wafer center | Vertical Stroke (Z-axis) | ||

| 893 mm | 320 mm | |||

| Carrying Speed (Ave.) | Arm (R-axis) | Vertical Stroke (Z-axis) | ||

| 950 mm/sec(when cylindrical operation) | 320 mm/sec | |||

| Repeatability | Within ±0.05 mm | |||

| Cleanliness | ISO Class 1 | |||

| Utility | Power: AC200~240V -15%/+10% 50/60Hz; Vacuum: -53 kPa or more | |||

| Mass | Approx. 70 kg | |||

| Outline Drawing (Standard) |

|---|

|

Option

Other Option

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single end-effector

- ...Twin end-effector

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking