Stepping Motor and Servo Motor

Stepping motor and servo motor are used for the drive motor of our robot.

Stepping motor is mainly used for robot for semiconductor: SCR3000 series, STCR4000 series, or GCR4000-PM series, while servo motor is mainly used for MCR3000 and 4000 series, GCR4000-AM series, or GTCR5000-AM series.

Servo motor is also used for robot for semiconductor depending on the size of carrying object or handling method.

In our product model name, “PM” is added in the end for the robot using the stepping motor and the servo motor as “AM”.

Click here for a list of stepping motor products.

Click here for a list of servo motor products.

Stepping motor

What is stepping motor?

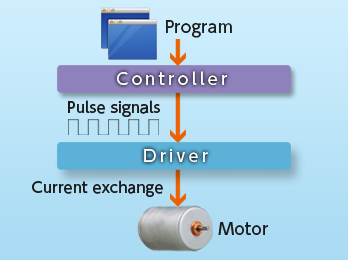

Stepping motor is also referred to as pulse motor. In response to pulse signals that are input to motor driver (the device that drives and controls the motor), the rotation-axis of motor rotates.

Mechanism of stepping motor

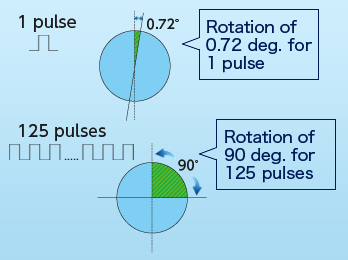

The angle of rotating axis for 1-pulse input of stepping motor is determined. If rotating the stepping motor 90 degrees with rotation of 0.72 degrees for 1 pulse, signals of 125 pulses will be input.

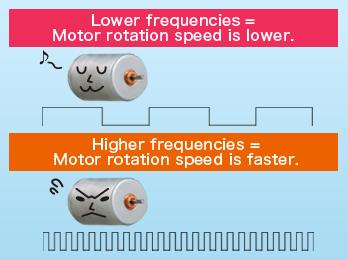

The speed of motor rotation is proportional to the speed of pulse signals (pulse frequency). The higher the frequency, the faster the motor rotation speed is and the lower the frequency, the lower the motor rotation speed is.

Characteristics of stepping motor

- 1. Torque is maximum at dwell time.

- 2. Widely covering rigidity of mechanical parts.

- 3. Mechanically simple and reasonably priced.

Click here for a list of stepping motor products.

Servo motor

What is servo motor?

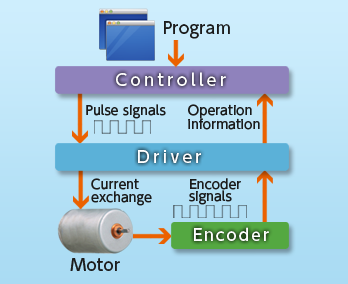

For servo motor, the rotation-axis/rotation speed of the motor drive are detected with rotation detection device (encoder) and fed back to the motor driver. The servo motor controls so that the difference between the feedback and control information that have been previously input to motor driver are zero.

Servo motor also can give more careful control than stepping motor and maintain high torque during high speed rotation.

Characteristics of servo motor

- 1. Suitable for long distance handling or when high-speed and high-torque are required.

- 2. More expensive compared to stepping motor as the encoder device is required for motor control.