System

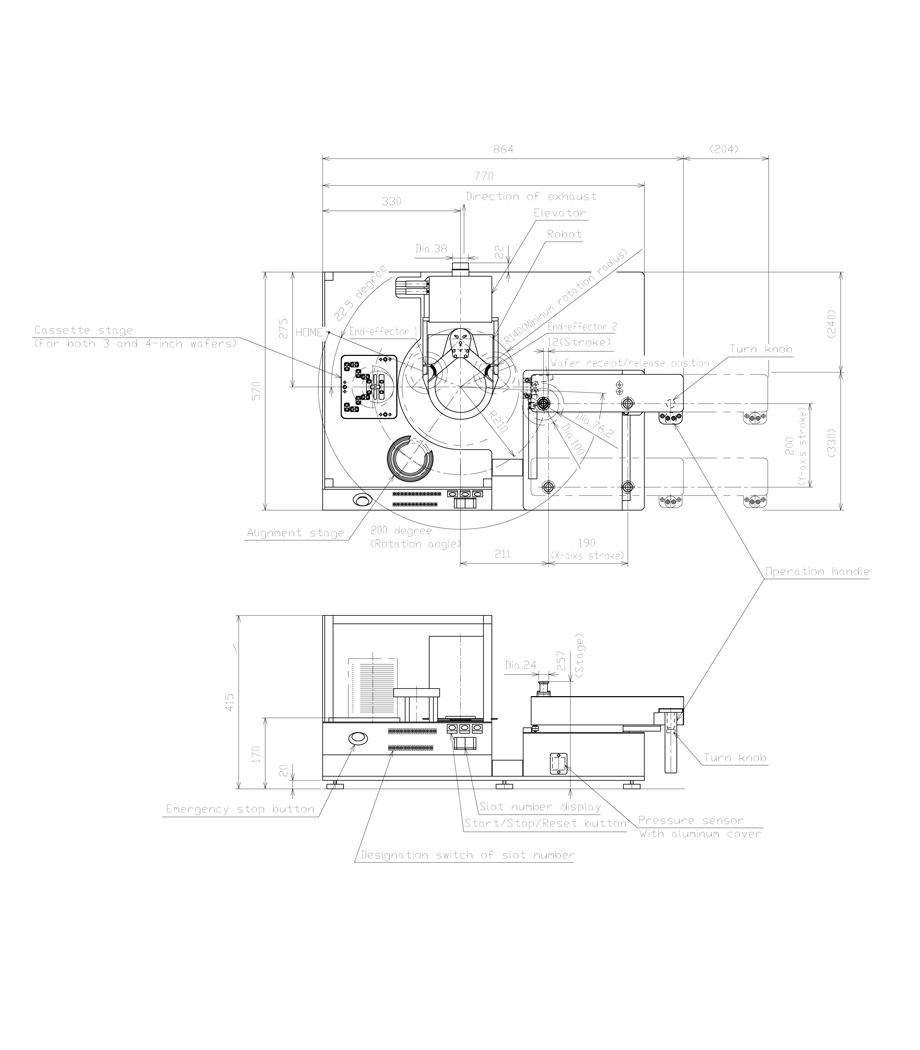

SSY-10000 (Table-top loader system for 100mm wafer)Wafer Transfer System

|

Usage Environment/SpecificationsProduct Profile

|

Product Video

- The image above and the video are of SSY-10000 (Table-top loader system for 100mm wafer).

Characteristics

For various types of wafers; 2, 3 inch, 100mm glass, sapphire, SiC, or GaN or others.

Customization is available.

- Compact system integrating wafer inspection stage into wafer handling system.

- Long stroke of 190mm X-axis and 200mm Y-axis. Wafer stage position can be manually adjusted with a handle.

- Twin end-effector reduces the wafer swap time.

- Low-cost & high-performance system combining robot and passive type alignment stage.

Standard Specifications

| Carrying Object | Up to 100mm wafer (glass, sapphire, SiC, or GaN or others) | ||

|---|---|---|---|

| Operating Range | From the robot center to the wafer center | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) |

| 225mm | 360deg | 150mm | |

| Carrying Speed (Ave.) |

Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) |

| 225mm/sec | 500deg/sec | 200mm/sec | |

| Carrying Speed (Max.) |

Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) |

| 300mm/sec | 700deg/sec | 300mm/sec | |

| Wafer Holding Method | By vacuum suction | ||

| Repeatability | Within ±0.1mm | ||

| Cleanliness | ISO Class 2 (at wafer transfer level when exhausting driving part) | ||

| Mass | Approx. 15kg (Robot) | ||

| Utility | Power: AC100V±10% 0.2kVA Vacuum: -53kPa or more | ||

| Outline Drawing (Standard) |

|---|

|

Option

Other Option

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking