Others

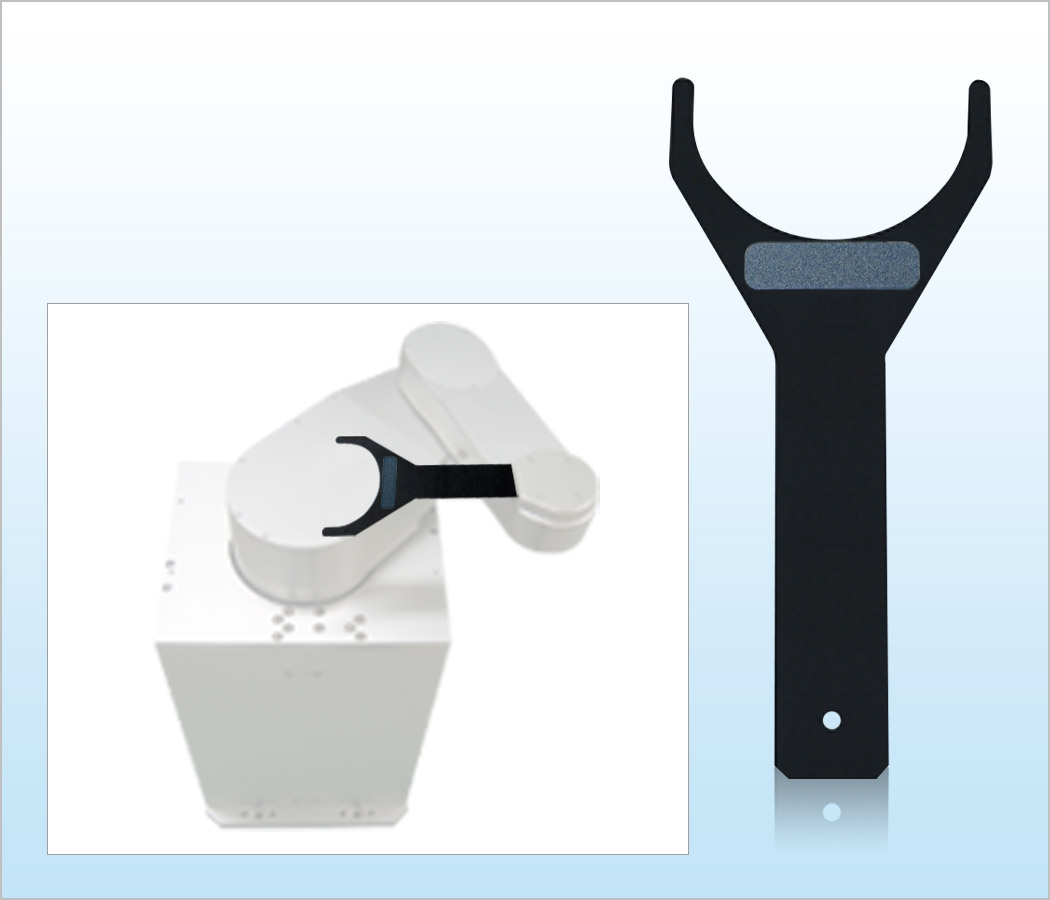

Porous End-Effector

|

Usage Environment/SpecificationsProduct Profile

|

Characteristics

Suitable for handling warped wafer or thin wafer that cannot be held properly with the standard vacuum suction type end-effector.

High purity alumina ceramic sintered body is used for the main body of end-effector, and porous ceramic is used for the wafer suction surface.

Compared with end-effectors that suction wafer by digging a ditch on the suction surface by approximately 1.5mm, the average micropore diameter of 20 µm can disperse suction pressure centering around the ditch. With this, Porous end-effector can hold thin wafer without deformation.

Particle size of mesh is selectable from Grade#100, #220, to #400.

Conductive Teflon coating is available for suction surface.

Standard Specifications

| Material | High purity alumina ceramic sintered body |

|---|---|

| Material of Suction Surface | Porous ceramic |

| Wafer Holding Method | Vacuum suction |

| Thickness | 3mm |

| Particle Size of Mesh | 44 to 74µm(Grade#220) |

| Average Micropore Diameter | 20µm(Grade#220) |

Contact us for the detailed specifications.

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking