Robot for FPD

LHR3400C (FPD glass substrate)3-Axis Cylindrical Coordinate Clean Robot

|

Usage Environment/SpecificationsProduct Profile

List of Product Model

|

|||||||||||||||||||||||||||||||||||

Characteristics

Designed for handling FPD substrate in a PFD production line or inspection line.

Telescope type is available for Z-axis of 760mm or longer, which allows the low-passline.

Execution of origin search is not required by using the servo motors with absolute encoders.

- Arm lineup: 400mm, 500mm, 700mm

- Base or flange mounting type is selectable.

- Motion monitoring is available.

- RS232C and parallel photo I/O are standard for control.

- AC servo motors with absolute encoders installed in all axes.

- High-speed, high-accuracy glass handling by S-curved speed control.

- Wafer holding: end-effector with vacuum suction, passive edge, edge grip, or Bernoulli type End-effector

- End-effector material: CFRP, Al, ceramic, or others.

- Sensors (for alignment, substrate existence detection, mapping) can be installed in the end-effector.

- Optimal end-effector is selectable according to the carrying object and line layout.

Standard Specifications

| Specifications of Robot | ||||

|---|---|---|---|---|

| Robot Model | LHR3400C-600-AM | |||

| Carrying Object | 730mm×920mm×1.1mm FPD glass substrate(representative example) | |||

| Robot Model Type | Cylindrical coordinate type | Control Axis | 3-axis | |

| Motor Type | AC servo motor | |||

| Operating Range | From robot center to substrate center | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 1550mm | 330deg | 600mm | ||

| Carrying Speed (Ave.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 1375mm/1.8sec | 180deg/1.5sec | 600mm/1.7sec | ||

| Resolution | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| Below 8.2µm | 0.0008deg | 2.4µm | ||

| Handling level | 217mm (Mounting level to upper end-effector level | |||

| Repeatability | Within ±0.2mm | |||

| Cleanliness | 0.3µm/cf Class 10 (at transfer level when exhausting driving) | |||

| Utility | Power: AC200V single phase ±10% 3 kVA; Vacuum: -73 kPa or more | |||

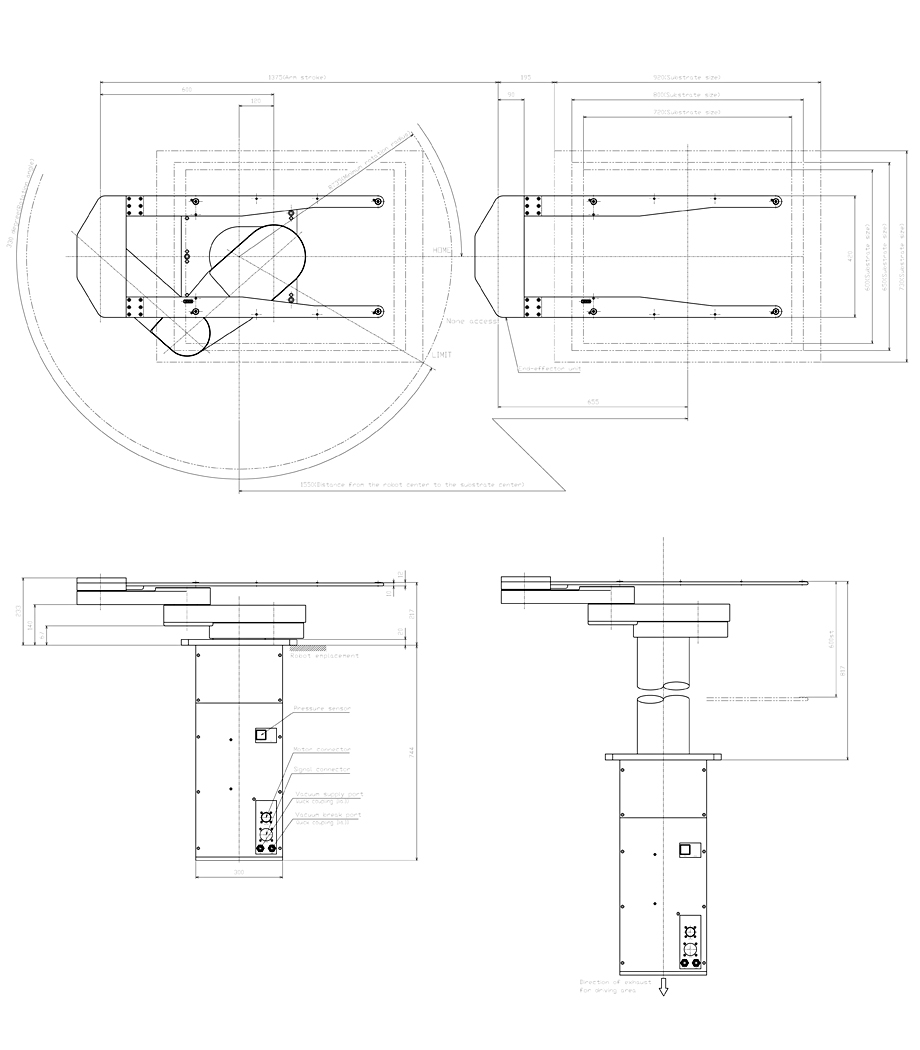

| Outline Drawing (Standard) |

|---|

|

Option

End-Effector

*Click the items below to review the end-effectors other than JEL standard types.

Other Option

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single arm

- ...Twin arm

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking