Robot for Semiconductor

GTVCR53305-Axis Horizontal and Multi-Joint Type Clean Robot

|

Usage Environment/SpecificationsProduct Profile

|

List of Product Model

| Product Model & Vertical Stroke | |||

|---|---|---|---|

| GTVCR5330-060-AM | 60mm | ||

Product Video

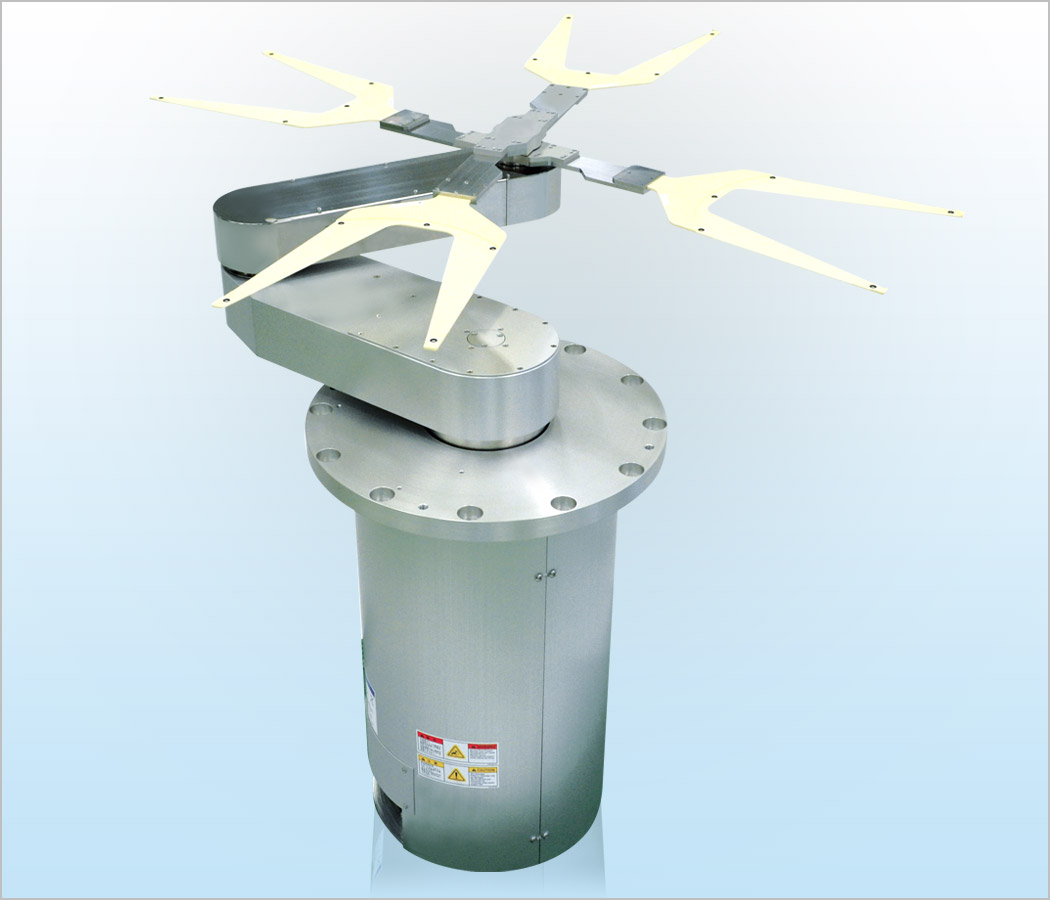

- The image above and the video are of GTVCR5330-060-AM (*The robot in the image and video uses the four end-effectors.)

Characteristics

Achieved cost reduction while maintaining the performance and functions of conventional robot GTVHR5000 series.

Transfers to the parallel stages in the vacuum chamber and supports various layouts, reducing footprint and vacuuming volume.

Simplification of the chamber layout leads to the cost reduction.

Suitable to the inline layout.

Execution of origin search is not required by using the servo motors with absolute encoders.

- Arm lineup: 280mm, 330mm

- Magnetic fluid sealing is used for arm joint.

- Vacuum sealing: Magnetic fluid sealing and bellows are used.

- For cleanliness: 5µm mesh filter installed for exhaust ventilation in the arm.

- Twin end-effector reduces the wafer swap time.

- Motion monitoring is available.

- RS232C and parallel photo I/O are standard for control.

- AC servo motors with absolute encoders installed in all axes.

- High-speed, high-accuracy wafer handlingby S-curved speed control.

- Wafer holding: end-effector with passive edge or edge grip type end-effector, and friction retaining by O-ring.

- End-effector material: CFRP, Al, ceramic, or others.

- Optimal end-effector is selectable according to the carrying object and line layout.

Standard Specifications

| Specifications of Robot | ||||

|---|---|---|---|---|

| Robot Model | GTVCR5330-060-AM | |||

| Carrying Object | Wafer up to 300mm | |||

| Robot Model Type | Horizontal and multi-joint type | Control Axis | 5-axis | |

| Motor Type | AC servo motor | |||

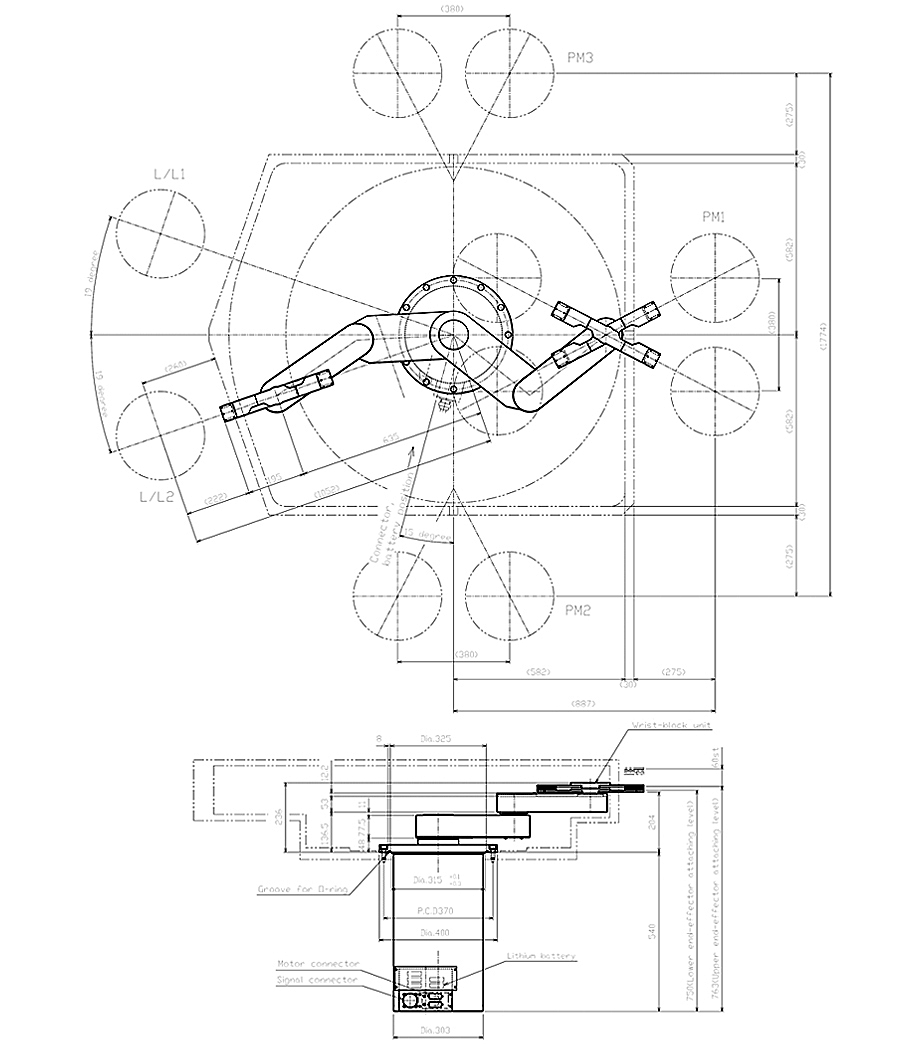

| Operating Range | 3rd Joint Center | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 635mm | 360deg | 60mm | ||

| Carrying Speed (Ave.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 640mm/sec | 160deg/sec | 60mm/sec | ||

| Carrying Speed (Max.) | Arm (R-axis) | Rotation Angle (Theta-axis) | Vertical Stroke (Z-axis) | |

| 950mm/sec | 200deg/sec | 85mm/sec | ||

| Resolution | 1st Joint Axis (J1-axis) 2nd Joint Axis (J2-axis) |

3rd Joint Axis (J3-axis) 3rd Joint Axis (J5-axis) |

Z-Axis (J4-axis) | |

| 0.00081deg 0.00081deg |

0.00072deg 0.00072deg |

0.98µm | ||

| Repeatability | Within ±0.1mm | |||

| Handling Level | 219mm (Mounting level to upper end-effector level) | |||

| Cleanliness | Magnetic fluid sealing and filter | |||

| Vacuum resistance | 1 x 10-6Pa | |||

| Utility | Power: AC200 to 230V 2kVA 50/60Hz | |||

| Specifications of Controller | ||||

| Controller Model | C5000S series | |||

| Interface | RS232C and parallel photo I/O | |||

| Outline Drawing (Standard) |

|---|

|

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Single end-effector

- ...Twin end-effector

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking